Precision Laser Welder for Corner Welding

Product Overview

1. Core Welding Advantages

Designed specifically for corner welding scenarios, it adopts high-precision laser emission technology, with a minimum welding spot diameter of 0.1mm. It can accurately focus on the corner joint, avoiding material overflow and deformation issues of traditional welding. It achieves smooth welds without spatter or weld marks, meeting the corner connection needs of high-precision products such as medical equipment and electronic components.

2. Intelligent Operation and Adaptability

Equipped with an automatic corner positioning system, it supports welding of various corner angles including 90° and 135°. It is compatible with multiple metal materials like stainless steel, aluminum alloy and titanium alloy. It has a touchscreen operation interface, allowing presetting of welding parameters. Even novice operators can master it quickly, greatly reducing manual operation errors and improving welding efficiency.

3. Stability and Safety Assurance

The machine body is made of high-temperature-resistant alloy material, with built-in overheating protection and laser shielding devices. It still maintains stable performance after 8 hours of continuous operation. The compact equipment can be flexibly moved to different workstations. Meanwhile, it complies with international laser safety standards, providing double protection for workshop operations.

Key Feature

1. High-precision numerical control welding: Through the numerical control system to accurately plan the welding trajectory, to ensure that the rounded welding uniform, beautiful, good weld formation, no virtual welding, leakage welding phenomenon, welding accuracy up to millimeter.

2. Customized welding procedures: According to different stainless steel material, thickness and fillet size, users can set their own welding parameters and paths to meet diversified welding needs and achieve personalized customized production.

3. Automatic wire feeding and constant current control: equipped with efficient automatic wire feeding system to ensure continuous and stable wire transmission; Constant current control technology ensures stable welding current, stable welding process and consistent weld quality.

4. Intelligent monitoring and fault diagnosis: real-time monitoring of the welding process of current, voltage, temperature and other parameters, once abnormal, the system automatically alarm and stop, while providing fault diagnosis information for quick investigation and repair.

application scenario

1. Stainless steel furniture manufacturing: used to make stainless steel chairs, tables, cabinets and other furniture rounded corner welding, improve product appearance quality and structural stability, to meet the high-end furniture market on the strict requirements of the welding process.

2. Kitchen and bathroom equipment production: Excellent performance in the round corner welding of stainless steel sink, gas stove shell, range hood and other kitchen and bathroom equipment, to ensure the sealing and durability of the equipment, to ensure product quality and service life.

3. Decoration engineering: Suitable for stainless steel railings, handrails, decorative lines and other round corner welding, to provide a beautiful and solid welding solution for architectural decoration engineering, improve the overall decorative effect.

4. Machining and manufacturing: It plays an important role in the round corner welding of stainless steel structural parts such as mechanical parts and metal frames, helping machinery manufacturing enterprises to improve production efficiency and product quality, and enhance market competitiveness.

Product Parameter

| Body Size |

1400x1100x2000 |

| Voltage |

220V |

| Power |

400W |

| The Clamping Way |

pnuema-lock |

| Control Method |

Starart CNC System |

| Compressed Air Pressure |

0.2-1.0Mpa |

| Floor Space |

1400x1100mm |

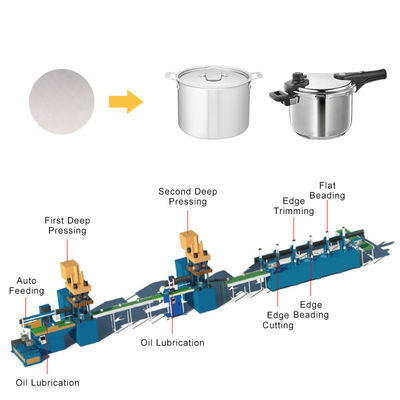

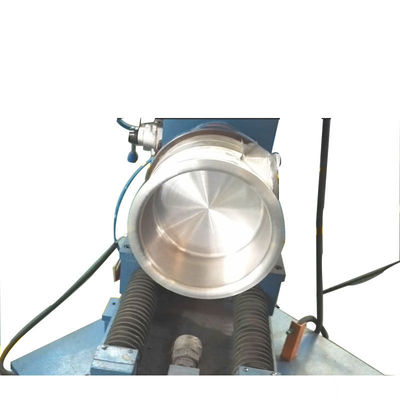

Product Photos

Custom Process

• On-demand customization: specify customized design solutions for customers, and provide customers with choices.

• Determine the customized program: According to the needs of customers, our design team will develop a customized program, including welding process parameters, equipment configuration, etc.

• Order delivery : The customer orders and pays according to the customized plan, so that the work goes smoothly.

• Arrange production: After confirming the plan and quotation, enter the manufacturing stage. We will strictly follow the customized program for production, to ensure that the equipment meets customer requirements. After the production is completed, strict quality testing is carried out to ensure stable and reliable equipment performance.

• After-Sales Serveice: Deliver the equipment to the customer in accordance with the agreed time, and provide after-sales support services.

Our company has been operating for many years, rich production experience, one-stop service to let you worry free after sale, looking forward to your call, our company will serve you wholeheartedly.

Company Advantage

Foshan Star Power Technology Co., LTD. has many years of experience and professional technical team in the field of welding equipment, and is committed to providing customers with quality products and services. Our fillet welding machine has passed strict quality inspection and market verification, and has a good reputation and customer satisfaction. And our company has a complete sink production chain and its machines, choose our company's corner welding machine, is to choose an efficient, stable and reliable welding solution to help your business development.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!